UL型轮胎联轴器

PDF下载

产品描述

UL型轮胎联轴器(GB/T5844-2002)

| ♦结构特点 Design feature •柔性,阻尼大,补偿量大。 •结构简单,装配容易。要更换轮胎体时无需轴向移动联轴节。 •缺点:随扭转角的增加,在主从动轴上产生相当大的轴向力。 •Plastic components ( tyres ) and metal plates made into a whole by sulfurating and felting. Connecting the 2 half-couplings directly by bolts when installing. •Flexibility, large damping, large compensation dosage. •Simple designing, easy for assembling and disassembling. The tyres can be replaced without moving 2 half-coupling. •Disadvantage, large Axial power will be brought on the driven end as the rotate angle increasing. |

|

♦标记示例Mark sample UL联轴器的轴孔、键槽的形式和尺寸符合GB/T3852-1997的规定。 -UI5轮胎式联轴器 主动端:Y型轴孔、A型键槽,d=28mm, L=62mmo 从动端:J1型轴孔、B型键槽,d=32mm, L=60mmo 联轴器:GB/T5844-2002 Shaft hole, modes and sizes of the key way of UL type coupling should accord standard of GB/T3852-1997. •Sample UI5 tyre shaft coupling Drive end: Y type shaft hole, A type key way, dis 28mm, L is 62mm. Driven ends: JI type shaft hole, B type key way, d is 32mm, L is 60mm. Marked as: UL5M28x62GB/T5844-2002 /1B32X60 |

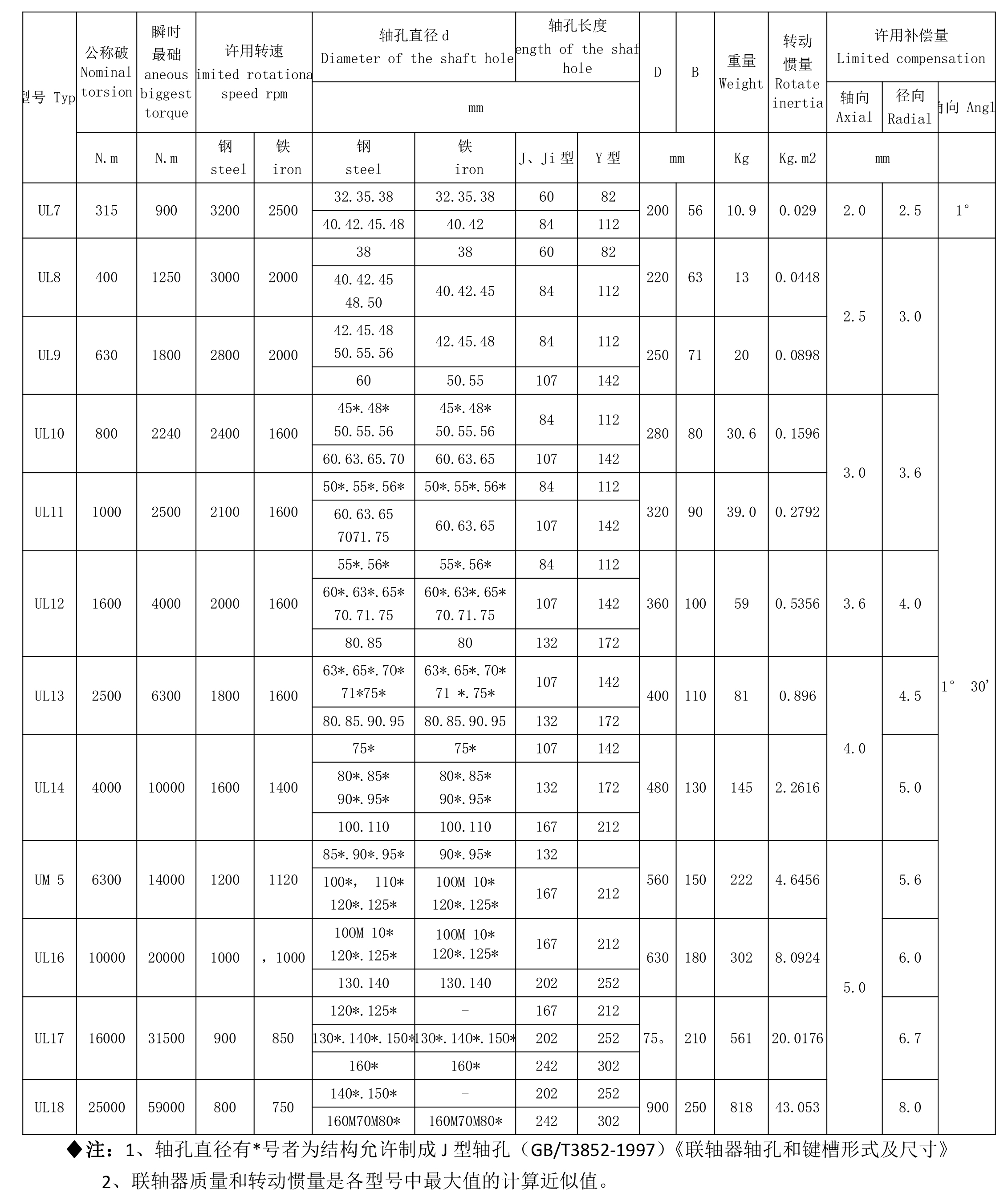

UL型轮胎式联轴器的主要尺寸和基本参数

| 型号 type | 公称扭矩 Nominal torsion |

瞬时最 大转矩 istantanc s bigges torque |

许用转速 Limited >tational speed rj |

1 孔直径 d Diameter of the shai hole | 月孔长度L Length o the shaft hole | D | B | 重量 Weight kg |

专动惯僅 Rotate inertia | 许用补偿量Limited compensation | |||||

| mm | 轴向 Axial | 径向 Radial |

角向 Angle | ||||||||||||

| N. m | N. m | 钢 steel | 铁 iron |

钢 steel | 铁 iron | J、Ji 型 | Y型 | mm | Kg | Kg.m2 | mm | ||||

| UL1 | 10 | 31.5 | 5000 | 3500 | 11 | 11 | 22 | 25 | 80 | 20 | 0.7 | 0. 0003 | 1.0 | 1.0 | 1° |

| 12、14 | 12、14 | 27 | 32 | ||||||||||||

| 16、18 | 16 | 30 | 42 | ||||||||||||

| UL2 | 25 | 80 | 5000 | 3000 | 14 | 14 | 27 | 32 | 100 | 26 | 1.2 | 0. 0008 | |||

| 16、 18、 19 | 16、 18、 19 | 30 | 42 | ||||||||||||

| 20、22 | 20 | 38 | 52 | ||||||||||||

| UL3 | 63 | 180 | 4500 | 3000 | 18、19 | 18、19 | 30 | 42 | 120 | 32 | 1.8 | 0. 0022 | 1.6 | 2.0 | |

| 20、22、24 | 20、22 | 38 | 52 | ||||||||||||

| 25 | 一 | 44 | 62 | ||||||||||||

| UL4 | 100 | 315 | 4300 | 3000 | 20、22、24 | 20、22、24 | 38 | 52 | 140 | 38 | 3 | 0. 004 | |||

| 25、28 | 25 | 44 | 62 | ||||||||||||

| 30 | — | 60 | 82 | ||||||||||||

| UL5 | 160 | 500 | 4000 | 3000 | 24 | 24 | 38 | 52 | 160 | 45 | 4.6 | 0. 0084 | 1.6 | 2.0 | |

| 25、28 | 25、28 | 44 | 62 | ||||||||||||

| 30、32、35 | 30 | 60 | 82 | ||||||||||||

| UL6 | 250 | 710 | 3600 | 2500 | 28 | 28 | 44 | 62 | 180 | 50 | 7. 1 | 0. 0164 | |||

| )、32、 35、: | 30、32、35 | 60 | 82 | ||||||||||||

| 40 | 84 | 112 | |||||||||||||

UL型轮胎联轴器(GB/T5844-2002)

UL型轮胎式联轴器的主要尺寸和基本参数

UL型轮胎式联轴器的主要尺寸和基本参数

2、联轴器质量和转动惯量是各型号中最大值的计算近似值。

♦ Note: l.According (Modes and sizes of coupling hole and keyway》of GB/T3852-1997, the hole diameter with can be made into J type structure.

2.lt is max calculating approximate value of weight and rotate inertia of all type couplings.

♦ Note: l.According (Modes and sizes of coupling hole and keyway》of GB/T3852-1997, the hole diameter with can be made into J type structure.

2.lt is max calculating approximate value of weight and rotate inertia of all type couplings.

咨询热线

咨询热线